For many years, hospitals in low and middle-income countries have used medical oxygen concentrators to treat patients with pneumonia, hypoxemia and, more recently, severe COVID-19.

These devices take in air from the room and filter out nitrogen, providing patients with extra oxygen to compensate for the restricted breathing caused by their illness.

Oxygen concentrators are more suitable and cost-effective than oxygen cylinders or Pressure Swing Adsorption (PSA) plants in places with limited infrastructure.

Another disadvantage of most oxygen concentrators is that key components are easily damaged, requiring maintenance. Spare parts are often not available locally. This means the oxygen concentrators stop working until the required parts are imported from international manufacturers, which can be a lengthy process.

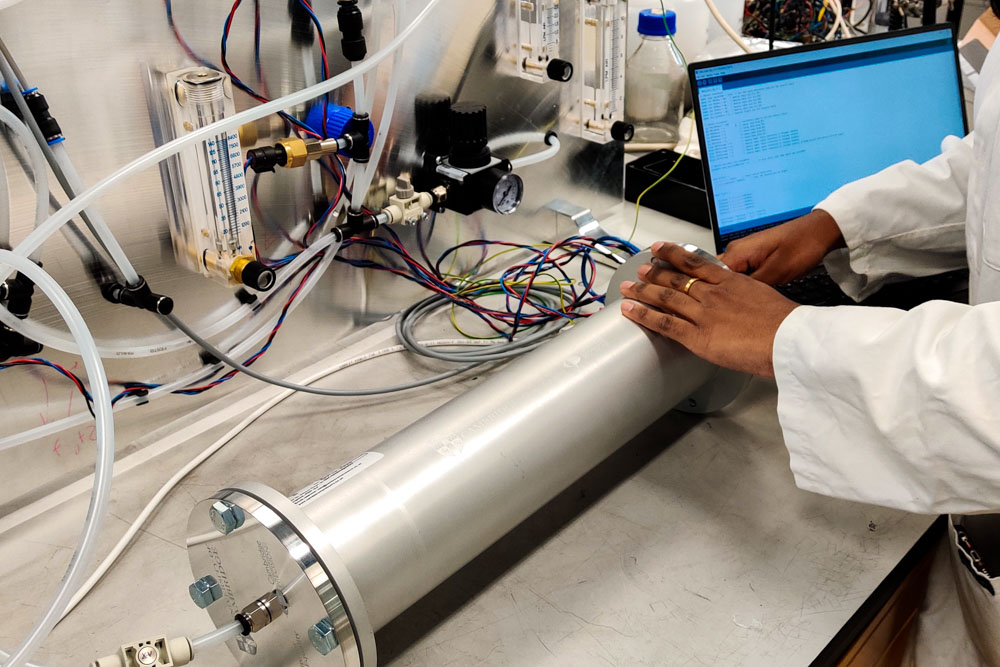

Our O2 Concentrator's distinctive design features include: